cGMP cell-based assay laboratory

Middleton, Wisconsin

Executive Summary

PPD’s cGMP cell-based assay laboratory was contracted to improve the performance of a previously developed potency assay for a client’s biological product. The two key issues were: (1) the assay was time consuming; and (2) it was formatted using a limited assay range that did not assess relative potency to the standard expected by regulatory authorities. In addition, the biological product was formulated with a bioresorbable carrier, and the required protein extraction processes were slow and inefficient.

PPD optimized the assay, reducing test complexity and duration while improving robustness and maintaining high-throughput testing. Extraction of the active protein was also enhanced, and the format allowed for parallel line analysis between standard and samples. This optimized assay met pre-established qualification specifications for linearity, precision, and specificity, and it has been used successfully to test the release and stability of multiple product lots over an 18 month period.

Introduction

Cell-based assays are bioassays designed to characterize the potency of biological drug substances and products. Biological products include cell-based therapies, genetic materials, proteins, peptides, and other biomolecules that occur in a variety of forms (either by themselves or as conjugates) and span a wide range of uniformity (from relatively homogeneous to widely heterologous mixtures).

Bioassays are one component of product and process characterization/validation and can be used to: select candidates; establish comparability; test process intermediates, formulations and stability/degradation; and support product changes. They are also a key part of establishing quality (ie, reproducibility and stability), which is critical to supporting the safety and efficacy profiles of biopharmaceuticals (USP 1032), and are necessary for regulatory submissions to support lot release (21CFR 600.2(s); 610.10; 610.1; 610 subpart B; ICHQ6B). A broad range of assay types can be used, including: ligand binding (multiple assay and signaling formats); cytotoxic assays (including apoptosis antibody and complement-dependent cytotoxicity assays); cell migration/proliferation/inhibition and metabolic signaling assays; and, for molecular products, assays to establish transduction/transfection efficiency and potentiation/expression.

International regulatory bodies recognize that the varied nature of biological products causes significant challenges while developing assays. Potential issues are usually due to factors inherent to biologic products, including: variability of the starting materials; limited availability for testing; product instability; potential for multiple active ingredients; effects of synergy or interference within or between drug products; the complexity of the product’s activity; and what happens to the product after it is administered. These assays also are susceptible to typical assay development hurdles, including differences due to experimental material (animals or cells) and variability across instruments, lots of reagents, analysts, days, and laboratories.

This paper discusses the efforts of PPD’s cGMP cell-based assay laboratory to meet these challenges and create a robust and reproducible assay for a client’s biological product that improved the performance of the existing potency assay and conformed to regulatory expectations and current guidance.

Project Description

The biological product, which was in early phase development, was a fairly uncomplicated recombinant human protein (rhuprotein) with three formulation strengths (DP-0.5, DP-1.0 and DP-2.0). The existing potency assay measured the induction of alkaline phosphatase activity in responder cells. We were asked to address two issues: (1) the assay took nine days to perform (inclusive of cell culture), a long duration that can be a source of additional variation; and (2) it had a limited range that did not assess relative potency to the standard expected by regulatory authorities.

An additional − and ultimately more complicated − wrinkle came with the unusual product formulation. This rhuprotein was formulated with a bioresorbable carrier, and the protein had to be extracted from the carrier before the potency assay could proceed. The extraction process was inefficient, taking three days and recovering protein at concentrations too low to allow for the generation of a full sigmoidal dose/response curve (the limited range).

Optimizing the Potency Assay

The original assay method was:

- Cells were thawed and cultured for 3 days individually (and for single use);

- 24-hour pre-incubation of the cells on the plates (to promote adherence);

- 3 days of incubating the protein in culture (to generate activity);

- After an overnight cell lysis, responses were generated by applying a freshly prepared signaling reagent;

- The quantifiable response range was limited to between 0.04 and 250 ng/mL.

The optimization process, which was fairly straightforward, used standard evaluations of assay conditions, such as the need for pre-incubation time, the effect of cell numbers on the stimulation time and response range, and the required lysis time. A one-step commercial reagent was also tested to simplify signal generation.

Figure 1 shows the effect of incubation time on signal generation at a low seeding density (5000 cells/well). After 24 hours, the dose/response curve was nearly flat. After 48 hours, the classic sigmoidal shape had developed, but 72 hours of incubation improved the range of responses and the goodness of fit of the four-parameter curves. Increasing the cell density to 7200 cells/well decreased the optimal incubation time to 48 hours (Figure 2), but we chose 5000 cells/well with a 72-hour incubation period because that combination yielded the most efficient throughput for the entire assay.

Figure 1. Drug dose/response measured by alkaline phosphatase signal generation using 5000 cells/well and incubating for A) 24, B) 48, and C) 72 hours at 37oC, 5% CO2.

Figure 1. Drug dose/response measured by alkaline phosphatase signal generation using 5000 cells/well and incubating for A) 24, B) 48, and C) 72 hours at 37oC, 5% CO2.Note: There was insufficient precision and signal generation for the software to derive a curve from the response to the reference standard.

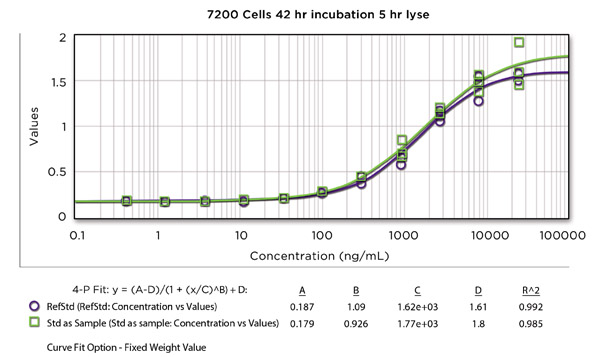

Figure 2. Drug dose/response measured by alkaline phosphatase signal generation using 7200 cells/well and incubating for 48 hours at 37oC, 5% CO2.

Figure 2. Drug dose/response measured by alkaline phosphatase signal generation using 7200 cells/well and incubating for 48 hours at 37oC, 5% CO2.

Through the optimization process, the assay time was shortened by two days. As might be expected for a method using a 72-hour incubation, the 24-hour pre-incubation period could be eliminated, and 4-hour lysis step (instead of overnight) was shown to be adequate. In addition, the performance of the commercial signaling reagent was equivalent to a freshly prepared reagent. Ultimately, the method was shown to have sufficient robustness to allow for application of a 7-point concentration curve (plating triplicate dilutions), permitting the evaluation of potency to be performed on 3 samples, relative to reference standards, on a single 96-well plate. Assay performance deteriorated after only a few passages, so the cells could not be used to test a single vial of drug substance over time.

Optimizing the Sample Preparation Method

The original method for recovering the biological drug substance from the bioresorbable carrier was dissolution, which was performed by soaking and shaking the rhuprotein product in a large volume of cell culture medium containing 10% fetal bovine serum. This process was repeated four times during initial cell culture, and the recovered protein from each step was assayed individually and then totaled to determine the active protein recovered. This method resulted in recovery of 55-70% of the expected protein activity, but concentrations were too dilute to provide sigmoidal dose/response curves.

Our objective was to improve drug recovery and generate samples of sufficient concentration to provide a full dose/response curve. To accomplish this goal, and to shorten and simplify the recovery of active protein, we evaluated the chaotropic agents urea (with and without tween-20) and guanidine-HCl. We also compared two wash buffers, HCl and acetate, to the cell culture medium previously used for dissolution, measuring their ability to reduce or eliminate the chaotrope from the protein extract solution to restore protein activity and allow for the determination of absolute protein recovery.

Extraction using urea, with or without tween (Figure 3), recovered the protein from the biological carrier (confirmed by HPLC, data not shown). Unfortunately, the chaotrope negatively and irreversibly affected the potency response of the extracted rhuprotein, even after extensive use of buffer exchanges to remove the urea from the extracted sample. The signal suppression observed at the highest concentrations of protein resulted in poor correlation coefficients and an inaccurate estimation of the EC50.

Figure 3. Dose response comparison of reference standard and drug substance extracted using urea with tween-20 after multiple (4-6) buffer exchanges using 1 mM HCl buffer.

Using guanidine-HCl instead of urea resulted in similar protein recovery (confirmed by HPLC, data not shown), and this chaotrope was effectively removed by a 1 or 10 mM HCl buffer as well as cell by culture medium (data not shown). Acetate buffer was not effective (data not shown). Eight buffer exchanges with either culture medium or 1 mM HCl appeared to completely restore protein activity relative to the standard (data not shown). We chose to use HCl because it provided a response equal to culture medium while allowing for direct determination of protein concentration and, thus, for an estimate of the total protein recovery resulting from the extraction process.

Our final optimized sample preparation method used guanidine-HCl extraction followed by 8 HCl buffer exchanges (Figure 4) and was efficient in terms of time (the entire process could be completed in one day) and protein recovery (it yielded concentrations sufficient to generate a full dose/response curve). We assessed the reproducibility of the method by comparing recovered protein concentrations (measured by absorbance at a 280 nm wavelength) across triplicate extractions performed at three dosage levels by two analysts (Table 1). While the average total protein recovery of 86% (range 66-100%) was an improvement over the 55-70% recovery of the original method, extraction remained a significant source of variability.

Figure 4. Dose/response curve using the estimated concentrations of samples and standard prepared using guanidine-HCl extraction and 8 HCl buffer exchanges. DP-2.0 V1, DP-2.0 V2, and DP-2.0 V3 are different sample extractions.

Figure 4. Dose/response curve using the estimated concentrations of samples and standard prepared using guanidine-HCl extraction and 8 HCl buffer exchanges. DP-2.0 V1, DP-2.0 V2, and DP-2.0 V3 are different sample extractions.

Table 1. Recovered protein concentrations determined by measuring absorbance (280 nM) on three independently guanidine-HCl-extracted, HCl-buffer-exchanged samples performed across drug dosages and analysts.

Even with 8 buffer exchanges, signal suppression occasionally could be observed as an activity hook at the highest sample concentrations (Figure 5). We hypothesize that this issue was caused by incomplete removal of guanidine-HCl and the resulting negative effect on the response. Limitations in the assay development timeline made it impossible to investigate alternative extraction methods to eliminate this hook effect. Instead, we instead focused on finding a concentration range that generated adequate data to support parallelism between the standard and samples but did not include higher values where the hook was observable. Our final assay had a linear range of 0.4 to 10 ug/mL and could generate a full sigmoidal dose/response curve with only 7 sample concentrations, maintaining the high throughput expected by the client.

Figure 5. Observed potency response interference in high-concentration extracted samples and mock-extracted standard after 8 buffer exchanges.

Figure 5. Observed potency response interference in high-concentration extracted samples and mock-extracted standard after 8 buffer exchanges.Testing Assay Robustness

With preliminary optimization performed, assay characterization was completed by: qualifying the cell bank for contamination; preparing and comparing two cell banks; and confirming the number of cell passages (9) that yielded acceptable assay performance. During the evaluation of critical reagents and materials, we also found that performance varied across lots of fetal bovine serum. As a result, all new lots of serum were pre-qualified to ensure acceptable system suitability in the assay.

The linear concentration range method was used to establish specifications for system suitability and application of parallel line analysis (Table 2). For the purposes of supporting the product in its early phase of development, the chosen specification criteria called for automated selection of the four best response concentrations within the linear range. The parallelism test, applied using PLA 2.0 software, evaluated the difference in the slope of the sample and standard dose/response curves. To be equivalent, the 95% confidence interval around the difference in slopes had to be within the pre-specified criteria of -1.2 to 1.2.

Table 2. System suitability criteria for 7-point linear range potency testing of extracted rhuprotein.

Qualification of the Cell Based Potency Assay

Given the early development phase of the product, we performed a limited qualification of the extraction and potency assays that included demonstration of specificity, accuracy, linearity and intermediate precision. The accuracy of sample potency relative to mock-extracted standard was tested across a 75-125% range of the nominal method concentration. The results showed a consistent 30% negative bias trend (double that observed from the total protein extracted), which was likely caused by the effect of residual guanidine-HCl on the activity of the protein in the bioassay. However, method linearity was demonstrated (Figure 6), so the consistency of the response across dilutions of the extracted product was suitable for the method’s application to early phase release and stability testing.

Figure 6. Linearity of extracted sample responses in the rhuprotein potency assay.

Figure 6. Linearity of extracted sample responses in the rhuprotein potency assay.The potency of extracted samples was affected by the compounded variability of the extraction process and the potency assay. With two analysts evaluating six preparations of each of three formulation strengths, the mean relative potency compared with mock-extracted standard ranged from 0.56 to 1.13 (Table 3). There was a trend towards lower recovered activity with increased drug concentration, and there appeared to be differences in precision and overall recovery between analysts. However, the performance reproducibility and intermediate precision were within the pre-established limit (<40% CV) for qualification and were sufficient to support early phase testing requirements.

Table 3. Intermediate precision determined across analysts using different instruments, cell culture and solution preparations.

Summary

In this case study, we described the methodology used to optimize and qualify a previously-developed cell-based potency assay for a biological product. During optimization, we successfully improved assay robustness (allowing for relatively high-throughput sample testing) and reduced assay complexity (shortening the assay duration by two days). Performance reproducibility was affected by variation between lots of fetal bovine serum, and this issue was managed by lot pre-qualification. We also improved extraction of the active protein from its bioresorbable carrier, but interference thought to result from residual guanidine-HCl at high drug concentrations prevented generation of a full sigmoidal dose/response curve. However, we were able to devise an assay format that allowed for parallel line analysis between standard and samples.

The results of method qualification confirmed the linearity and specificity of the assay and showed a reproducible negative bias trend for accuracy relative to mock-extracted standard. The observed imprecision of the extracted samples was affected by analyst and was more pronounced at higher drug concentrations, but the final results were within acceptable pre-specified limits for an early phase product. To date, this method has been used to successfully test the release and stability of multiple product lots across an 18-month testing period.

In the future, the performance of this assay may be improved by increasing assay sensitivity to allow the testing of more dilute samples and/or increasing the number of buffer exchanges to further reduce or eliminate guanidine-HCl from the extracted samples. Either or both of these approaches are expected to restore the use of full potency dose/response curves, which will improve parallel line analysis for later-stage product development.

© 2013 Pharmaceutical Product Development, LLC. All rights reserved.

Download full white paper to learn more. Download full white paper to learn more.