Summary

Single-use technologies are changing the way how biopharmaceuticals development and production, particularly from mammalian cell culture, are being performed. Almost all process steps from cell expansion, fermentation, cell removal, purification to formulation and storage of drug substance can be done in disposables, although there are still severe limitations with single use technologies, particularly in the areas dependent on individual vendor systems, pretesting and quality control of disposables, bag and connections standardization and qualification as well as leachables and extractables validation.

The continuing progress in developing single-use technologies has an important impact on biomanufacturing facilities resulting in much faster, less expensive and simpler plant design, start-up and operation. This enriches the current landscape of available facilities from standard hard-piped to hardpiped/ disposables hybrid to completely single use-based production plants using the current standard segregation and containment concept. On top of this, disposables in combination with the completely and functionally closed systems concept facilitate a revolutionary design of ballroom facilities without or with much less segregation, which in full consequence would allow GMP production of different products simultaneously in unclassified areas.

Introduction

The supply scenario for many biopharmaceutical drugs such as monoclonal antibodies (MoAbs) is changing. With the implementation of personalized medicine resulting in drugs for specific, high responder subsets of patients, market volume per drug will decrease. In addition increasing fermentation titers of up to 10 g/L for MoAbs are leading to smaller fermentation volumes necessary to accommodate individual biopharmaceutical market demands. With that not only drug development including production of clinical supply, can be done in disposables at fermenter volumes of up to 3,000 L, but also low-volume commercial supply, which is currently produced in the typical 10-15,000 L hard-piped, standard steel-based production plants. In the following the benefits and risks of single-use technologies compared to highly automated, hardpiped processing will be addressed, as well as a discussion on different state-of-the art facility designs.

Advantages and Limitations of Single-use Technologies

Except some large-scale unit operations such as centrifugation, chromatography skids and UF/DF operations, all process steps can be done in disposables up to a bag volume of around 3,000 L. These include mixing/holding/distribution of culture media and buffers, cell seed expansion and production fermentation, cell removal by depth filtration, disposable chromatography columns and UF/DF/virus filtration. Though many single-use units have already been an integral part of biomanufacturing by integrating them into hard-piped set-ups (filters, etc.), the real progress towards completely disposable processing came with the development of single-use bioreactors (SUBs), where now several systems are available up to a fermenter scale of 2,000 L.

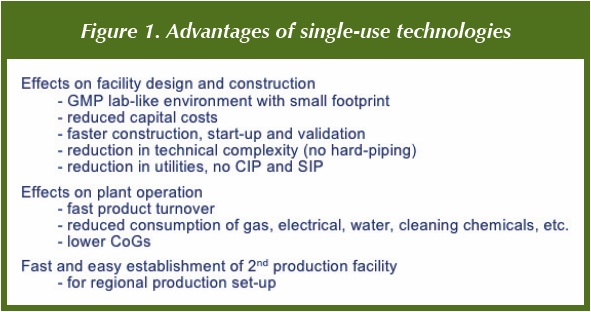

The advantages of using disposables are summarized in Figure 1. One major advantage is that pre-sterilized, single-use systems can be used in a lab-like environment. This is well suited for small-scale research and development activities, since no supporting engineering infrastructure regarding, i.e., utilities, hard-piping and automation is needed to set up and run such operations. This enables even universities to be able to do bioprocessing at a reasonable scale in their labs. Another advantage is the time and costs savings in plant construction and operation. The main contributors here are capital costs, reduced consumption of utilities such as gas, electrical and water (purified, WFI) as well as reduced staffing. This was published in [1] as case study by Roebers et.al., presented at the IBC Life Sciences Bioprocessing Meeting, October 2009. The time savings vary depending on the extent of disposables use. Most facilities still contain non-disposable unit operations. In such a case of hybrid design time savings in the early engineering project up to mechanical completion are sometimes marginal, but time savings during start-up including qualification and validation can be very pronounced (up to 70 %), since equipment qualification using disposables is very limited, and no SIP and CIP processes are needed. Also, the sometimes very lengthy cleaning validation of vessels and pipes with product contact is not necessary for single use, since the bags are discarded after each run. Another advantage is the possibility to efficiently perform short product campaigns in multipurpose facilities including fast product turnover by simply using new bags. In summary, all this leads to overall much reduced CoGs, although the material costs in form of the single-use units are increased. However, this is more than compensated for by the lower capital depreciation alone, since the capital costs using disposables are in the range of 30-50 % compared to hard-piped arrangements.

Another advantage is the easy transfer of a manufacturing process to a second site, which is of increasing interest for producing a drug locally in the respective regional market. Since the same disposables-based units combined with low qualification and validation efforts can be used at the extension site, the risks in process transfer and achieving biochemical comparability, identical product quality and, finally, regulatory approval should be strongly reduced.

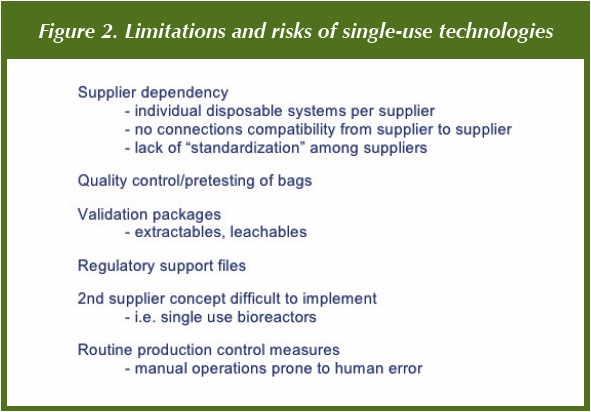

The disadvantages, risks and limitations of using disposables are summarized in Figure 2. First, there will always be a volume limit for handling and operating disposables. For fermenters and larger hold bags it is expected to be in the 3,000 L range. For portable systems, the limit is currently in the range of 1,000 L.

A big issue is the dependency on vendors. There are several integrated systems being developed by individual suppliers, which are not compatible, i.e., it is not possible to interconnect systems from different suppliers to a large functionally closed processing unit. In order to comply with the desired 2nd supplier concept in biomanufacturing for SUBs, one has to show biochemical comparability and product quality in 2 bioreactor types, before they can be used for commercial production. This is a big additional development and validation effort, until 2 adequate systems are licensed. In addition, it would be desired to get improved quality control by the suppliers. For example, bags should be pressure tested before delivery, in order to reduce failure rates. On top, it would be advantageous to get full supporting validation packages including extractables and leachables data as well as regulatory support files from the suppliers to make regulatory filing simpler.

Compared to automated, hard-piped systems, working with single use systems is labor intensive, since assembling of individual pieces to operational units is done manually. A very well-trained workforce is essential to avoid or minimize operator error. Finally, using disposables increases the material costs and leads to more waste, which has to be incinerated.

Impact of Single-use Systems on Plant Design and Operation

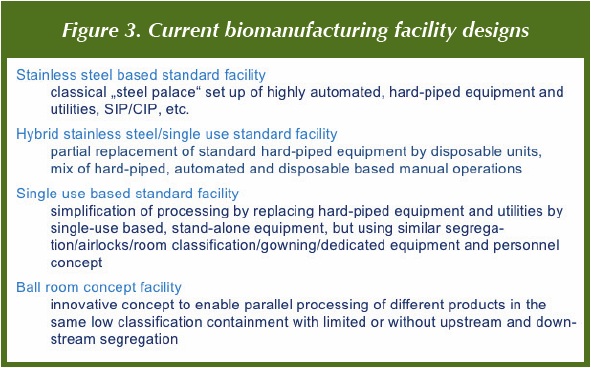

As mentioned above, one of the most important features in using disposable systems is the impact on plant design, costs and operation. However, since steel plants are currently state-of-the-art and since not all unit operations can reliably be performed as single-use, there are several plant designs currently realized, each having its own special characteristics (Figure 3).

Stainless Steel-based Standard Facility

This represents the established current state-of-the-art for biomanufacturing using, i.e., a fermentation six pack of 10-15,000 L fermenters with, in many cases, 2 purification suites. These facilities are very expensive, fully hard-piped and highly automated. They have the usual operational and area segregation and containment concept minimizing cross-contamination of any kind. Start up and validation are lengthy, including automated SIP (steam in place) and CIP (clean in place) processes, but lead to very reliable, operator error-independent processing. This is and will remain the choice for large volume products.

Stainless Steel/Single-use Hybrid Standard Facility

The first integration of disposables into biomanufacturing came by introducing disposable units into hard-piped facilities, simply to make operations more effi cient. A good example for this is harvest clarification replacing cross-flow microfiltration, which is difficult to maintain and clean, as well as centrifugation for cell removal by large depth filters. In the meantime, with more disposable systems available, true hybrid facilities are being built with hard-piped parts as well as flexible standalone units based on disposables, but still using the standard segregation and containment concept.

We at Bayer are currently building a 3,000 L pilot facility, where we have the option to run 2 production bioreactors in parallel, one hardpiped steel fermenter and one disposable SUB. This will be an excellent development tool to establish biochemical comparability and product quality in both systems, which is very important, if clinical production is done in disposables, but future manufacturing needs larger hard-piped fermentation systems. However, in all these hybrid plants the potential time and cost savings by using disposables is limited, since the hard-piped part determines time and costs.

Single-use Based Standard Facility

In order to fully utilize the advantages of single-use systems the fi rst mainly disposable based plants are being built implementing the advantages of smaller foot print, lab-like environment, reduced costs and time schedules, but still using the established segregation and containment concept. They fully realize all advantages of using disposables and rely mostly on manual operations. However, there are still some non-disposable unit operations integrated such as large UF/DF or chromatography skids, which are individually cleaned and maintained using portable COP (clean out of place) units, avoiding the complex hardpiped CIP infrastructure.

Ball Room Concept Facility

The ball room concept represents an innovative concept to enable parallel processing of different products in a shared low classification containment without or with only limited segregation. It was recently described in a publication by Chalk et al. [2]. It is based on the key assumption that technological advances including single-use systems have continuously reduced the risk of environmental impact on processing, the main reason for the high segregation in standard plants. Nowadays most process steps can be securely performed closed or functionally closed. The few remaining open processing steps have to be addressed independently.

The basic thinking is that in a closed or functionally closed system, the process stream is isolated from the environment so that environmental control is of less importance. Remaining open operations such as cell expansion, column packing or powder addition have to be addressed separately, i.e., using separate small areas with classical containment or using isolator technologies. Basically, potential breach of the closed system is the major risk to be addressed by intense microbial monitoring, as well as proving that no contamination or cross-contamination have occurred. Maintaining the closed system status is very important and has to be addressed by a risk-based approach with appropriate risk mitigation strategies considering each process step or operation. In the case study [2] the following risks were addressed and mitigation strategies provided using detailed failure mode and effects analysis tools: temporary breakable connections, open manipulation in the process stream, charging raw materials during media and buffer preparation, equipment preparation, cleaning or maintenance, in-process sampling as well as unexpected breach of a closed system element.

Indeed, the first facilities were licensed by regulatory agencies following that concept of much lower segregation and room classification compared to the standard segregation approach.

Conclusions

Single-use technologies are maturing, allowing almost all cell culture process steps to be performed in disposable instead of hard-piped unit operations. This leads to simpler operation in a lab-like environment. However, since the disposable industry is still maturing, there are many open issues such as validation, secure supply at high standard and standardization, which have to be improved.

Disposable-based flexible facilities with functionally closed operation units are developing into a viable alternative to the standard hard-piped facilities, particularly for lower volume products. Such facilities are faster to build, have a smaller footprint and a less complex engineering. In addition, they are simpler to qualify and validate, lower in costs and easier to operate, especially in a multipurpose environment with frequent product changes. They still have the same or a similar segregation concept compared to classical plants.

Finally, the most advanced ball room plant design with less or no segregation and containment seem at least technically possible, because of improvements in closed systems handling, if corresponding risk mitigation strategies are applied. This may lead to less or unsegregated plants with low containment requirements allowing parallel operation of more than 1 product at a time. However, issues such as how to handle steps, where functionally closed operation is not possible or available, as well as regulatory acceptance still have to be addressed.

References

1. Leveen L. “Single use technology and its carbon and water footprints, Part 2”. American Pharmaceutical Review. 2009;13:50–6.

2. Simon Chalk, et.al., “Challenging the Cleanroom Paradigm for Biopharmaceutical Manufacturing of Bulk Drug Substance”, BioPharm International Aug 2011, p 1-13.

Dr. Berthold Bödeker is heading pilot plants and cell culture at Global Biologics - Biotech Development of Bayer Pharma AG in Wuppertal, Germany, which is responsible for development and clinical material production of microbial and mammalian proteins. In addition he is also responsible for contract development and production of Biologics for external clients as well as for outsourcing projects.